Features

- Specially engineered frame design for maximum structural integrity and minimum bend deflection.

- Machine controlled by user-friendly CNC units.

- Hydraulic compensation of the lower beam for enhanced accuracy.

- Quick release top tool clamping.

- Pneumatic top and lower tool clamping.

- Wila-system hydraulic top and lower tool clamping with Wila tooling.

- Sliding and fully adjustable front arms on linear guides as standard.

- Automatic and motorised sheet followers by CNC.

- Start-stop technology for power saving.

- Online servicing over internet VPN connection.

- Hydraulic, electrical, mechanical components from globally-known brands with high standards

- Laser guarding DSP AP or LAZER SAFE

Deflection frame control

Bending of sheets of various length without changing the parameters

Bending of sheets of various length without changing the parameters- Bending of sheets that have been notched or drilled without changing the parameters

- Possibility to test bending operations on pieces of reduced sizes, and then carry out the same bending operation on the real pieces without changing the parameters

- No delay in working time

- This system is not visible and does not create any obstruction to the bending options

- No decrease in speed

- No visible and obstructive measuring equipment

Machine Controls

- All Farina press brakes are controlled by powerful CNC units recognised for being user-friendly with easy programming and having application flexibility for machine operators.

- Delem DA 69T – 3D multi axis graphical control

- Delem DA 69T – 2D multi axis graphical control

- Software for offline programming

- Autopol INFOLAB BEND cad/cam bending simulation software

Thickness measurement system

Thickness measurement system

- Increased precision

- Totally automated

- Decrease in waste of material

- Check of material

- No delay in bending process

- No visible and obstructive measuring equipment

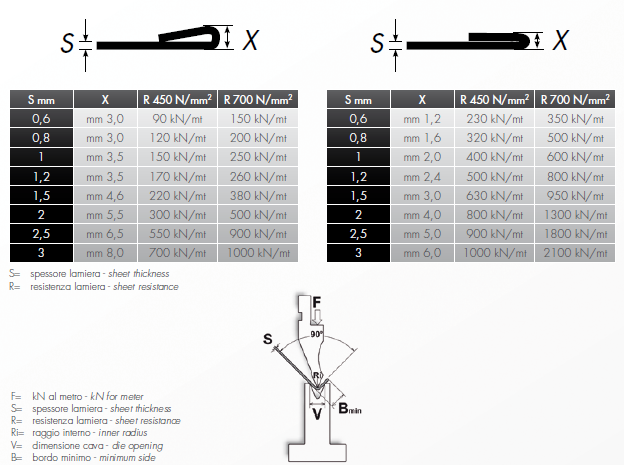

| S | Mm | 0.6 | 1 | 1,5 | 2 | 3 | 4 | 5 | |||||||

| V | Mm | 6 | 8 | 6 | 8 | 10 | 12 | 12 | 16 | 20 | 25 | 32 | 40 | 40 | 50 |

| F kN/mt | R 200 N/mm2 | 20 | 10 | 60 | 40 | 70 | 60 | 110 | 80 | 140 | 110 | 150 | 110 | 190 | 140 |

| R 450 N/mm2 | 40 | 30 | 130 | 80 | 160 | 130 | 250 | 170 | 320 | 240 | 340 | 250 | 420 | 320 | |

| R 700 N/mm2 | 60 | 40 | 190 | 130 | 250 | 200 | 390 | 260 | 500 | 370 | 530 | 390 | 660 | 490 | |

| Ri | Ri mm | 1,0 | 1,3 | 1,0 | 1,3 | 1,7 | 2,0 | 2,0 | 2,7 | 3,3 | 4,2 | 5,3 | 6,7 | 6,7 | 8,3 |

| B | 900= B min mm | 4,5 | 6,0 | 4,7 | 6,2 | 7,8 | 9,2 | 9,5 | 12,3 | 15,6 | 19,2 | 24,6 | 30,3 | 30,8 | 37,9 |

| 600= B min mm | 6,3 | 8,3 | 6,5 | 8,5 | 10,8 | 12,8 | 13,0 | 17,0 | 21,5 | 26,5 | 34,0 | 42,0 | 42,5 | 52,5 | |

| 350= B min mm | 10,3 | 13,6 | 10,5 | 13,8 | 17,4 | 20,7 | 21,0 | 27,6 | 34,8 | 43,1 | 55,2 | 68,5 | 69,0 | 85,6 | |

| S | Mm | 6 | 8 | 10 | 12 | 15 | 20 | 25 | |||||||

| V | Mm | 50 | 63 | 63 | 80 | 80 | 100 | 100 | 125 | 160 | 200 | 200 | 250 | 250 | 320 |

| F kN/mt | R 200 N/mm2 | 210 | 160 | 310 | 220 | 380 | 280 | 430 | 320 | 390 | 290 | 560 | 420 | 700 | 510 |

| R 450 N/mm2 | 480 | 360 | 690 | 500 | 840 | 630 | 960 | 720 | 870 | 660 | 1260 | 950 | 1580 | 1150 | |

| R 700 N/mm2 | 750 | 550 | 1070 | 780 | 1310 | 980 | 1490 | 1120 | 1350 | 1020 | 1960 | 1480 | 2450 | 1790 | |

| Ri | Ri mm | 8,3 | 10,5 | 10,5 | 13,3 | 13,3 | 16,7 | 16,7 | 20,8 | 26,7 | 33,3 | 33,3 | 41,7 | 41,7 | 53,3 |

| B | 900= B min mm | 38,4 | 47,5 | 48,5 | 60,6 | 61,6 | 75,7 | 76,7 | 94,4 | 120,6 | 148,9 | 151,4 | 186,8 | 189,3 | 238,8 |

| 600= B min mm | 53,0 | 66,0 | 67,0 | 84,0 | 85,0 | 105,0 | 106,0 | 131,0 | 167,5 | 207,5 | 210,0 | 260,0 | 262,5 | 332,5 | |

| 350= B min mm | 86,1 | 107,8 | 108,8 | 137,0 | 138,0 | 171,3 | 172,3 | 213,8 | 273,5 | 340,1 | 342,6 | 425,7 | 428,2 | 544,6 | |

TECHNICAL DATA

| Bending Force | Bending Length | Distance Between frames | Throath | Table RAM distance | Cylinders stroke | Approach speed | Work speed | Return Speed | Power | Approx Weight | L | W | H | |

| MODEL | Kn | Mm | Mm | Mm | Mm | Mm | Mm/s | Mm/s | Mm/s | Kg | kW | Mm | Mm | Mm |

| 30/835 | 300 | 835 | 700 | 350 | 450 | 250 | 180 | 0-10 | 150 | 5,5 | 2500 | 1450 | 1400 | 2550 |

| 40/16 | 400 | 1670 | 1450 |

300 |

380 | 200 | 160 | 0-10 | 150 | 4 | 3050 | 2450 | 1260 | 2200 |

| 40/20 | 400 | 2085 | 1670 | 3200 | 2900 | 1260 | 2300 | |||||||

| 65/25 | 650 | 2505 | 2100 | 380 | 200 | 160 | 0-10 | 150 | 7,5 | 4200 | 3400 | 1500 | 2350 | |

| 65/30 | 650 | 3150 | 2600 | 4450 | 3980 | 1690 | 2450 | |||||||

| 80/30 | 800 | 3250 | 2600 |

500 |

400 | 200 | 160 | 0-10 | 150 | 11 | 6950 | 3980 | 1750 | 2740 |

| 80/40 | 800 | 4100 | 3600 | 8400 | 4980 | 1750 | 2740 | |||||||

| 110/30 | 1100 | 3150 | 2600 | 445 | 250 | 160 | 0-10 | 150 | 11 | 7800 | 3990 | 1750 | 2800 | |

| 110/40 | 1100 | 4175 | 3600 | 10700 | 4980 | 1750 | 3100 | |||||||

| 130/30 | 1300 | 3150 | 2600 | 445 | 250 | 160 | 0-10 | 150 | 15 | 10400 | 3990 | 1750 | 2900 | |

| 130/40 | 1300 | 4175 | 3600 | 13100 | 4980 | 1750 | 3100 | |||||||

| 160/30 | 1600 | 3150 | 2600 |

500 |

455 |

250 |

160 |

0-10 |

150 |

15 |

12800 | 3950 | 1930 | 2800 |

| 160/40 | 1600 | 4100 | 3600 | 15400 | 4950 | 1930 | 3100 | |||||||

| 160/60 | 1600 | 6100 | 5600 | 20000 | 6950 | 1930 | 3450 | |||||||

| 200/30 | 2000 | 3150 | 2600 |

525 |

275 |

150 |

0-10 |

120 |

18,5 |

14900 | 4000 | 2050 | 3150 | |

| 200/40 | 2000 | 4100 | 3600 | 18500 | 4950 | 2050 | 3500 | |||||||

| 200/60 | 2000 | 6100 | 5600 | 25500 | 6950 | 2050 | 3700 | |||||||

| 250/30 | 2500 | 3150 | 2600 |

525 |

275 |

150 |

0-10 |

120 |

18,5 |

15200 | 4000 | 2150 | 3100 | |

| 250/40 | 2500 | 4100 | 3600 | 25000 | 4950 | 2150 | 3250 | |||||||

| 250/60 | 2500 | 6100 | 5600 | 31000 | 6950 | 2250 | 3480 | |||||||

| 320/40 | 3200 | 4100 | 3600 | 630 | 350 | 120 | 0-9 | 100 | 22 | 28000 | 4950 | 2350 | 3690 | |

| 320/60 | 3200 | 6100 | 5600 | 40400 | 6950 | 2480 | 4050 | |||||||

| 400/40 | 4000 | 4100 | 3600 |

630 |

350 |

90 |

0-8 |

80 |

30 |

32000 | 4950 | 2480 | 3700 | |

| 400/60 | 4000 | 6100 | 5600 | 41000 | 6950 | 2480 | 3850 | |||||||

| 400/80 | 4000 | 8100 | 7050 | 54000 | 8950 | 2480 | 4250 | |||||||

| 500/40 | 5000 | 4100 | 3600 |

630 |

350 |

90 |

0-7 |

70 |

37 |

40000 | 4950 | 2490 | 3700 | |

| 500/60 | 5000 | 6100 | 5500 | 51000 | 6950 | 2490 | 3850 | |||||||

| 500/80 | 5000 | 8100 | 7050 | 65000 | 8950 | 2490 | 4250 | |||||||

| 650/40 | 6500 | 4100 | 3600 |

630 |

350 |

90 |

0-7 |

70 |

45 |

48000 | 4950 | 2490 | 3850 | |

| 650/60 | 6500 | 6100 | 5100 | 60000 | 6950 | 2490 | 4150 | |||||||

| 650/80 | 6500 | 8100 | 7050 | 77000 | 8950 | 2490 | 4450 |

Bending of sheets of various length without changing the parameters

Bending of sheets of various length without changing the parameters