Cutting Machine – Guillotine Shears

- The machine is based on 3 basic principles:

1. Machine durability

2. Operational reliability

3. Perfect cut

All of this is made possible by our very strong frame design and by the mechanical engineering properties that we have built into our machines. As a result, the cutting cyle rates are also notably very high on the Farina shears with the help of the special hydraulics that we are using. - Farina shears come with many standard or optional equipment and features that make shearing a very productive cutting process

- Fratelli Farina factory started with the manufacture of shearing machines more than 40 years ago. The massive experience gained from all those years of technical evolution enabled us to study and realize special solutions for any shear-cutting requirement, reaching to very large thickness capacities.

Features

- Large and extra-strong frame design for maximum structural integrity and minimum deflection under load.

- 500 mm large throat (up to 4 meter length).

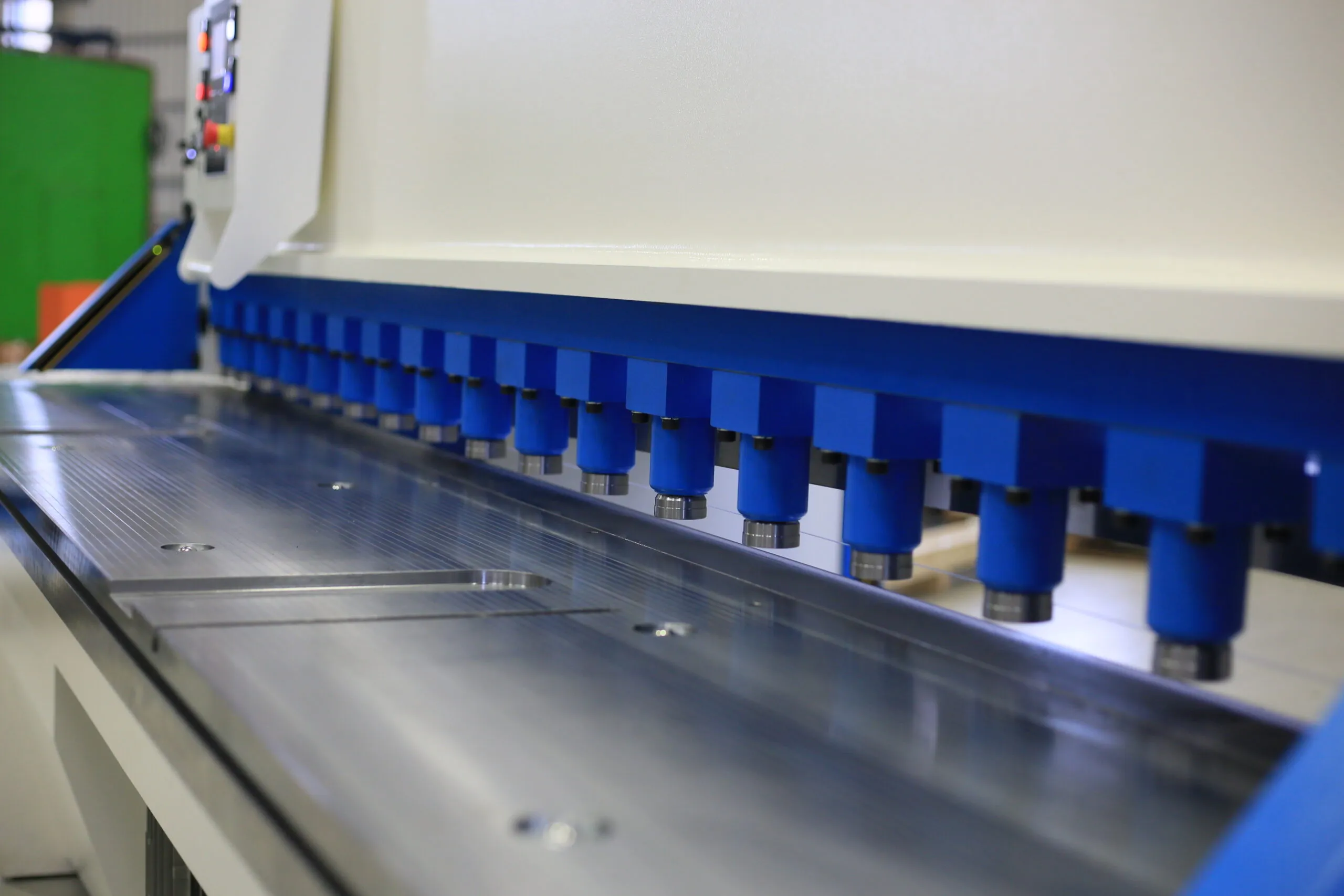

- Holddown clamps with independent hydraulic circuit.

- 2-speed motorised backgauge with rapid travel on recirculating screws and with retract function.

- Swing-away backgauge system.

- Full steel table with ball transfers for easy sheet handling.

- Side squaring arm and front support arms.

- Cutting blades in special-alloyed material.

- Stainless steel package.

- Pneumatic or hydraulic sheet sustainers.

- Sheet sustainer with double pneumatic movement for decent and inclination.

- Hydraulic anti-twist system at the lower beam.

- Start-stop technology for power saving.

- Front and rear light guards for safety.

Machine Controls

On a guillotine shearing machine the following parameters need to be controlled and/or adjusted in a certain way for the shear to operate effectively.

- Backgauge distance

- Cutting angle (rake)

- Blade gap

- Stroke counter

- Backgauge retraction

- Sheet sustainer

- Cutting length

- Mode selection:

1. Manual

2. Auto

3. Single

Control units

Farina shears utilize these control units depending on the level of automation required by our customers.

- Numerical shear control PRG 911

- Electronic programmable shear control Delem DAC 360s

| Model | Cutting length | Dıstance between side frames | Throat | Cutting force | Max thickness | Cutting angle | Cycles/min. | Backgauge | Power | Approx Weight | L | W | H |

| mm | mm | mm | Kn | mm | (min/max) | Mm | Kw | Kg | Mm | mm | mm | ||

| CFO 204 |

2100 |

2200 |

500 |

200 | 4 | 30’-3° | 35/60 | 750 | 7,5 | 4900 | 2750 | 2000 | 1900 |

| CFO 206 | 260 | 6 | 33/58 | 11 | 5700 | 2750 | 2000 | 1900 | |||||

| CFO 208 | 360 | 8 | 31/52 | 11 | 6900 | 2750 | 2000 | 1900 | |||||

| CFO 210 | 480 | 10 | 25/48 | 18,5 | 7900 | 2750 | 2200 | 1900 | |||||

| CFO 212 | 510 | 12 | 22/40 | 22 | 8800 | 3850 | 2200 | 2300 | |||||

| CFO 214 | 710 | 14 | 20/38 | 1020 | 22 | 10000 | 2850 | 2200 | 2300 | ||||

| CFO 216 | 860 | 16 | 19/37 | 30 | 12600 | 2850 | 2200 | 2400 | |||||

| CFO 220 | 2300 | 1400 | 20 | 15/25 | 37 | 15500 | 2900 | 2300 | 2500 | ||||

| CFO 225 | 1800 | 25 | 13/23 | 45 | 18000 | 2900 | 2400 | 2500 | |||||

| CFO 230 | 2400 | 30 | 9/18 | 55 | 21800 | 2900 | 2500 | 2800 | |||||

| CFO 304 |

3100 |

3200 |

500 |

200 | 4 | 30’-3° | 35/60 | 750 | 7,5 | 7000 | 3600 | 1800 | 1900 |

| CFO 306 | 260 | 6 | 33/58 | 11 | 8700 | 3600 | 1800 | 1900 | |||||

| CFO 308 | 360 | 8 | 31/52 | 15 | 9600 | 3600 | 2000 | 1900 | |||||

| CFO 310 | 480 | 10 | 25/48 | 18,5 | 11800 | 3800 | 2200 | 2200 | |||||

| CFO 313 | 560 | 13 | 22/40 | 1020 | 22 | 14000 | 3800 | 2200 | 2400 | ||||

| CFO 316 | 860 | 16 | 19/37 | 30 | 17800 | 3800 | 2200 | 2400 | |||||

| CFO 320 |

3300 |

1250 | 20 | 15/25 | 45 | 20800 | 3900 | 2400 | 2600 | ||||

| CFO 325 | 1800 | 25 | 13/23 | 45 | 26000 | 3900 | 2500 | 3900 | |||||

| CFO 330 | 2400 | 30 | 9/18 | 55 | 31500 | 3900 | 2600 | 3000 | |||||

| CFO 404 | 4100 |

4200 |

500 |

290 | 4 | 30’-2°30’ | 33/58 |

750 |

11 | 12900 | 4650 | 2000 | 1900 |

| CFO 406 | 300 | 6 | 33/58 | 15 | 13600 | 4650 | 2000 | 1900 | |||||

| CFO 408 | 380 | 8 | 25/48 | 15 | 16000 | 4650 | 2300 | 1900 | |||||

| CFO 410 | 460 | 10 | 22/45 | 18,5 | 18800 | 4700 | 2400 | 2200 | |||||

| CFO 413 | 850 | 13 | 20/41 | 22 | 21600 | 4700 | 2400 | 2300 | |||||

| CFO 416 | 1100 | 16 | 19/37 | 1020 | 30 | 24000 | 4900 | 2400 | 2400 | ||||

| CFO 420 |

4300 |

1300 | 20 | 16/26 | 37 | 28500 | 4900 | 2500 | 2600 | ||||

| CFO 425 | 1900 | 25 | 12/22 | 45 | 33000 | 5000 | 2700 | 2850 | |||||

| CFO 430 | 2300 | 30 | 9/16 | 55 | 38000 | 5000 | 2800 | 3200 | |||||

| CFO 604 |

6100 |

6300 |

100 |

290 | 4 |

30’-2° |

26/47 |

750 |

11 | 20800 | 6750 | 2500 | 2200 |

| CFO 606 | 300 | 6 | 25/45 | 18,5 | 23500 | 6750 | 2500 | 2200 | |||||

| CFO 608 | 380 | 8 | 23/40 | 18,5 | 28000 | 6750 | 2700 | 2400 | |||||

| CFO 610 | 460 | 10 | 22/38 | 22 | 32000 | 6850 | 2800 | 2500 | |||||

| CFO 613 | 850 | 13 | 22/35 |

1020 |

30 | 35000 | 6850 | 2900 | 2600 | ||||

| CFO 616 | 1100 | 16 | 18/30 | 37 | 41500 | 6850 | 2900 | 2700 | |||||

| CFO 620 | 1300 | 20 | 15/26 | 37 | 47000 | 6950 | 3000 | 2800 | |||||

| CFO 625 | 1900 | 25 | 12/22 | 45 | 52000 | 6950 | 3100 | 3000 | |||||

| CFO 630 | 2300 | 30 | 9/15 | 55 | 62000 | 6950 | 3200 | 3100 |