Precision, Durability & Efficiency

Revolutionizing Sheet Metal Folding

The Savika Folding Machine is designed for professionals in the sheet metal industry, delivering exceptional precision, durability, and efficiency. With cutting-edge technology and a robust construction, Savika is the ideal choice for industrial and custom metal fabrication.

Why Choose Savika?

Savika stands out in the market by combining precision engineering, advanced technology, and superior build quality.

BENEFITS

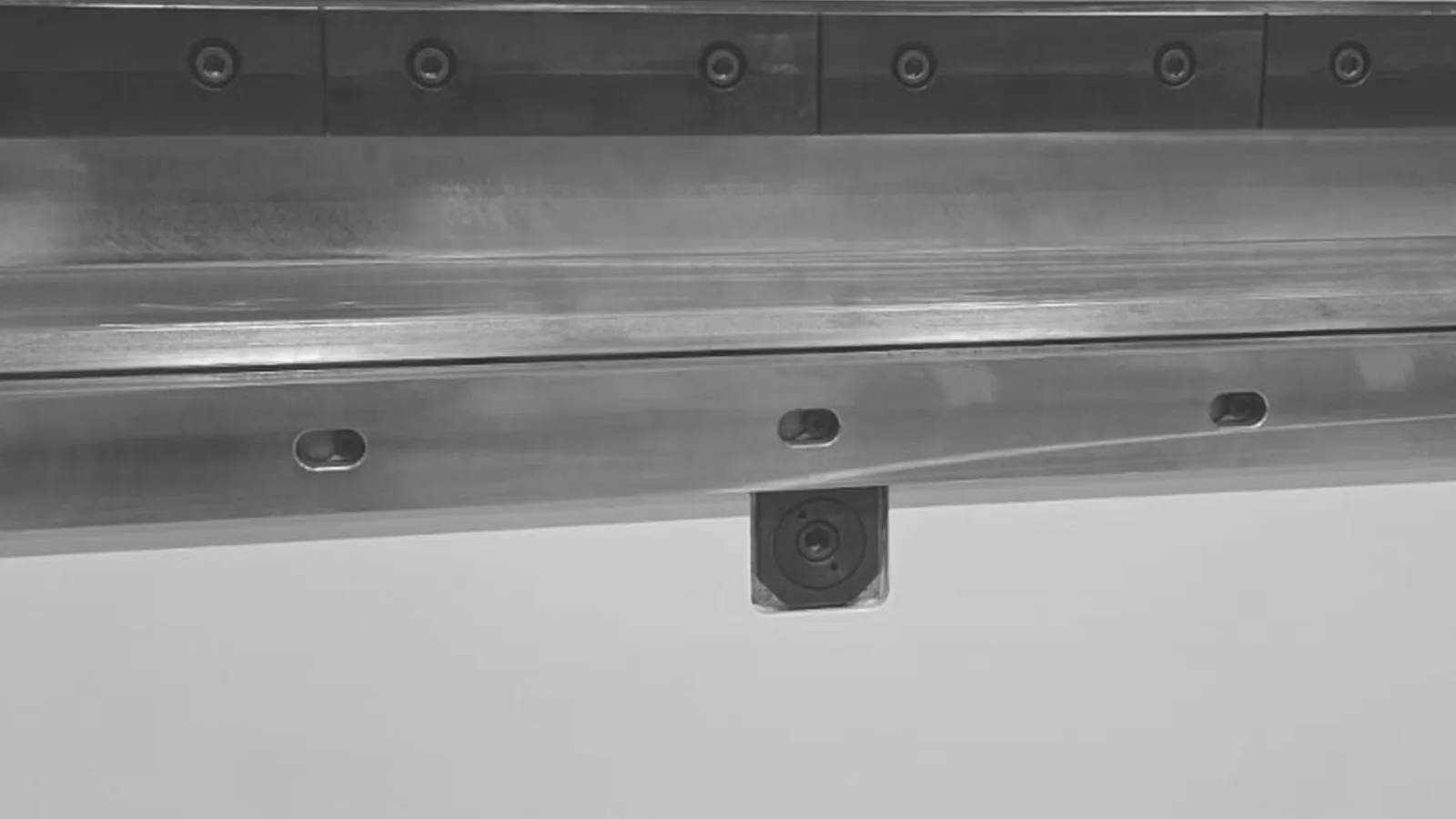

- Rotating combi beam solution with segmented box tools

- Strong structure for high quality bends

- Time-saving through 1-man operation Minimal maintenance effort

- Easy software for fast programming

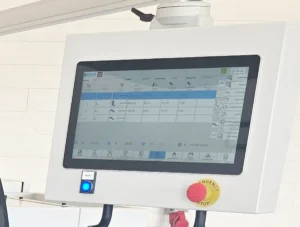

CONTROLS

Savika machines comes with 2 types of controller

- LBL – Line by line programming 12 “ touchscreen

- 2D graphic – graphic CNC software 15 “ touchscreen

SERIES EQUIPMENT

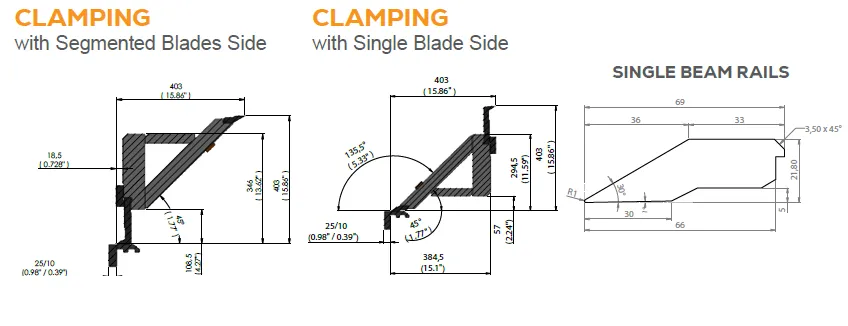

The following series equipment is possible depending on the version (working length/control): Sharp rail 30° R 1 mm offset

- Motorized backgauge 3 – 1000mm Insert rail 7/10 mm

- Insert rail 25 mm Fotpedal 3 pedal

- Ball transfers in backgauge table

ADD-ONS – OPTIMISE YOUR SAVIKA

The following add-ons are possible depending on the version (working length/control): Combi beam with segmented box tools

- 3 – 1550 mm motorized backgauge with 3 stations (under 3 sec for positioning)

- 2D Graphic software

- Motorized foldingbeam adjustment Squaring arm on backgauge side

- U shape backgauge L shape backgauge Radius rails

TECHNICAL DATA

| MODEL | Combi beam | S 2625 | S 3220 | S 4115 | |

| WORKING LENGTH | mm | 2600 | 3200 | 4100 | |

| OUTPUT | Steel (400N/mm²) | mm | 2,50 | 2,00 | 1,50 |

| Stainless steel (600N/mm²)mm | mm | 1,75 | 1,25 | 0,90 | |

| Cooper (300N/mm²) | mm | 2,50 | 2,00 | 1,50 | |

| Aluminium (250N/mm²) | mm | 3,50 | 2,00 | 1,50 | |

| Zinc (150N/mm²) | mm | 3,50 | 3,00 | 1,00 | |

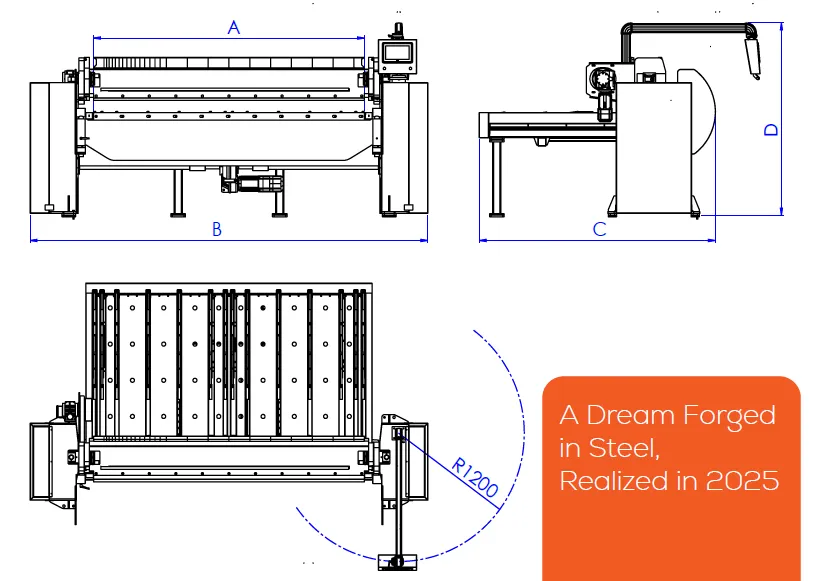

| DIMENSIONS | Length | mm | 3820 | 4420 | 5320 |

| Depth | mm | 2270 | 2270 | 2270 | |

| Overall height | mm | 1810 | 1810 | 1810 | |

| WEIGHT | kg | 3170 | 3500 | 4210 | |

| CLAMPING BEAMS | Opening height | mm | 140 | 140 | 140 |

- Ball transfer in backgauge

- Quick lock on insert rails for fast change of tools

- Multistation 3 stations backgauge with feathersprings in front for making no marks from underrail

- Rotating upperbeam for quick change between standard and boxtools ( under 10 sec to change)

- Box tools 100mm high freespace on C-model

- Strong folding beam for the best folding result

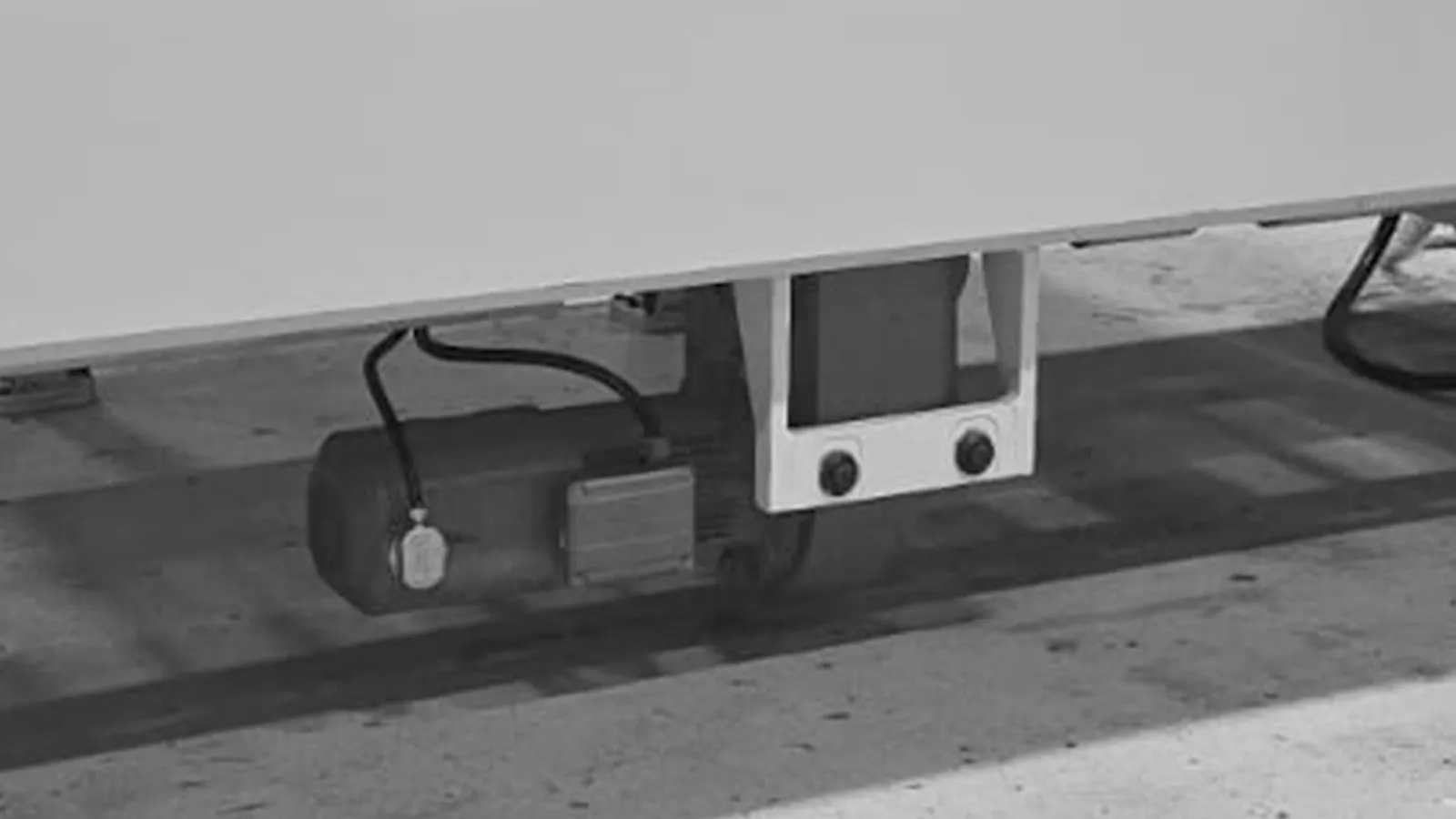

- Motor in middle for upperbeam give exact same force in both sides of the machine and more accurate folding.

- Customizable table on the back with expansion possibilities.

Safety buttons on each side of the frames to reach from any side

Large table also with U or L Shape configuration options enabled

Quick lock for Bottom Blade & Easy manual crowning setting

Standard safe guards on sides of bending area to protect operator

Easy adjustment of lower beam height and setback

Easily moving acrobat arm for controller with 1200mm radius enables to work in the back

3 Pedals standard foot controls enabled